General of ball valve

Ball valve are normally used in the following system: seawater, sanitary, trim and drain, air, hydraulic, and oil treatment. Ball Valve are widely used in fluid-andling systems for flow control. These types of rotary valves are suitable for corrosive applications. They are used in detergent, pharmaceutical, chemical, rubber, pulp and paper plants, water treatment systems, textile mills and food processing plants, In general, ball valves offer many advantages when contrasted with other valve types. They provide superior ease of operation and can maintain and regulate high volume, high pressure and high temperature flow. Most ball valves offer rugged construction providing for a long service life, and a comparably low cost. Additionally, the design of the regulating element allows the valve to function without the complications of side loads, typical of butterfly or globe valves, and the valve design permits inspection and repair of seats and seals without removing the valves body from the pipeline.

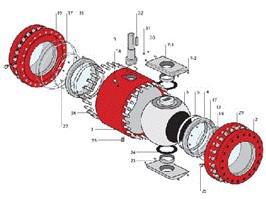

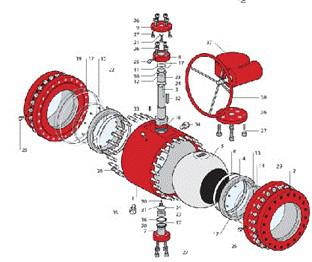

Forged steel trunnion mounted ball valve

|

NO |

NAME OF PART |

NO | NAME OF PART |

|

1 |

Body |

20 |

Trunnion Seal |

|

2 |

Closure |

21 |

Stem Packing |

|

3 |

Stem |

22 |

Seat Spring |

|

4 |

Seat Ring |

23 |

Bearing |

|

5 |

Ball |

24 |

Thrust Washer |

|

6 |

Seat Insert |

25 |

Sealant Fitting |

|

7 |

Trunnion |

26 |

SOcket Bolt |

|

7-1 |

Trunnion Block |

27 |

Hex/Socket Bolt |

|

7-2 |

Trunnion Block Pin |

28 |

Stud Bolt |

|

8 |

Gland |

29 |

Hex Nut |

|

9 |

Adapter Plate |

30 |

Grounding Pin |

|

10 |

Stem O-ring/ Lipseal |

31 |

Grounding Spring |

|

11 |

Stem O-ring |

32 |

Key |

|

12 |

Gland O-ring |

33 |

Dowel Pin |

|

13 |

Seat O-ring/LIPSEAL |

34 |

Relief Plug |

|

14 |

Seat Subseal |

35 |

Drain Plug |

|

15 |

Closure O-ring |

36 |

Mounting Plate |

|

17 |

Backup Ring |

37 |

Gear Operator |

|

18 |

Gland Seal |

38 |

Hand Wheel |

|

19 |

Body Seal |

COMPONMENT IDENTIFICATION

DESIGN AND MANUFACTURE STANDARDS

|

Basic Design |

API 6D |

|

Shell Wall Thickness |

API 6D |

|

Face to Face Dimension |

API 6D |

|

Flange End Dimension |

ANSI B16.5 (1/2" to 24") MSS SP-44 (26" & up) |

|

Butt-Weld End Dimension |

ANSI B16.25 |

|

Inspection & Testing |

API 6D |

|

Fire Safe Design |

API 6FA/BS 6755 |

BILL OF MATERIALS

|

NO |

NAME OF PART |

Carbon Steel NACE |

Low temp NACE |

Stainless Steel NACE |

|

1 |

Body |

A105.A350LF2 |

A350 LF2 |

A182F316 |

|

2 |

Closure |

A105.A350LF2 |

A350 LF2 |

A182F316.A351CF8M |

|

3 |

Stem |

AISI1045ENP, AISI4140ENP |

AISI 4140 ENP |

316 SS, 17-4 PHSS |

|

4 |

Seat Ring |

A105ENP.A106ENP |

A350 LF2 ENP |

316 SS |

|

5 |

Ball |

A105ENP |

A350 LF2 ENP |

A182F316.A351CF8M |

|

6 |

Seat Insert |

Nylon, PTFE, PEEK |

Nylon, PTFE, PEEK |

Nylon, PTFE, PEEK |

|

7 |

Trunnion |

AIS1 1045, AISI 4140 |

316 SS |

|

|

7-1 |

Trunnion Block |

AIS1 1045, AISI 4140 |

316 SS |

|

|

7-2 |

Trunnion Block Pin |

AISI 410 |

316 SS |

|

|

8 |

Gland |

AIS1 1045 |

316 SS |

|

|

9 |

Adapter Plate |

AIS1 1045 |

316 SS |

|

|

10 |

Stem O-ring/ Lipseal |

Viton/Polymite |

Viton GLT/ Polymite |

Viton/Polymite |

|

11 |

Stem O-ring |

Viton |

Viton GLT |

Viton |

|

12 |

Gland O-ring |

Viton |

Viton GLT |

Viton |

|

13 |

Seat O-ring/LIPSEAL |

Viton/Polymite |

Viton GLT/Polymite |

Viton/Polymite |

|

14 |

Seat Subseal |

Viton, Graphite |

Viton GLT, Graphite |

Viton, Graphite |

|

15 |

Closure O-ring |

Viton |

Viton GLT |

Viton |

|

16 |

Trunnion O-RING |

Viton |

Viton GLT |

Viton |

|

17 |

Backup Ring |

PTFE, Nylon |

PTFE, Nylon |

PTFE, Nylon |

|

18 |

Gland Seal |

Spiral Wound Gasket 316SS + Graphite |

||

|

19 |

Body Seal |

Spiral Wound Gasket 316SS + Graphite |

||

|

20 |

Trunnion Seal |

Spiral Wound Gasket 316SS + Graphite |

||

|

21 |

Stem Packing |

Graphite |

||

|

22 |

Seat Spring |

Inconel X-750, 17-7 PHSS |

||

|

23 |

Bearing |

PTFE/Carbon Steel |

PTFE/316SS |

|

|

24 |

Thrust Washer |

PTFE/Carbon Steel |

PTFE/316SS |

|

|

25 |

Sealant Fitting |

Carbon Steel/SS Ball Check |

316SS/SS Ball Check |

|

|

26 |

SOcket Bolt |

A574 |

316 SS |

|

|

27 |

Hex/Socket Bolt |

A574 |

316 SS |

|

|

28 |

Stud Bolt |

A193 B7M |

A320 L7M |

A193B8 |

|

29 |

Hex Nut |

A1942HM |

A1947M |

A194 8 |

|

30 |

Grounding Pin |

Stainless Steel |

||

|

31 |

Grounding Spring |

Stainless Steel |

||

|

32 |

Key |

Carbon Steel |

Stainless Steel |

|

|

33 |

Dowel Pin |

Carbon Steel |

Stainless Steel |

|

|

34 |

Relief Plug |

Carbon Steel |

Stainless Steel |

|

|

35 |

Drain Plug |

Carbon Steel |

Stainless Steel |

|

|

36 |

Mounting Plate |

Carbon Steel |

Stainless Steel |

|

|

37 |

Gear Operator |

Ductile Iron Case/Carbon Steel Worm Gear |

||

|

38 |

Hand Wheel |

Carbon Steel, Ductile Iron |

||

NOTE:MATERIALS ALSO AVAILABLE IN F321, F347, F51, F53, MONEL, INCONEL, INCOLLOY AND HASTELLOY.

NOTE: METAL-TO-METAL SEATED BALL VALVE DESIGNS ARE AVAILABLE UPON REQUEST.