Applocation :

Ball valve is made up of cock , its opening and closing is ball ,using ball aroud the axis of stem rotate 90 C to relization of opening and closing . Ball valve is mainly used for cuting , distribution and change the flow direction of medium in the line . Ceramic ball valve is a new knid of corrosion resistant ball valve .All of the ball , seat and everywhere the medium flow is made of ceramic in order to substrate from corrosion , sybstrate coated with a layer of enamel , then use ceramic lining . It is mainly used for electria power , petroleum , chemicial piping sustem such as the opeing and closing device .

Characteristics :

The valve is appliation as an on-of or piplines with high - hardness or with both soft graun and corrosive medium . Its mominal pressure is 1.6 Mpa , and applicable temperature ¡Ü200¡æ

All medium - contacting parts are made of industricial ceramic , featuring extremely high chemical stability and hardness ( Rockwell Hardness HRC90) ,only nest to diamond . there fore this valve has extremely strong resistance to abrasion corrosion and erosion , good heat insulation and small thermal expansion . The ball is made with advanced grinding equipment and process , with high precisiom ball roundness and good surface quality , and after facing -up with the valve seat ,a good sealability can be obtained by means of self - lubrication of ceramic .

Thanks to the ceramic¡¯s strong resistance to brasion , this valve is durable and extremely reliable with a long service life

Main Specification

|

Type |

Q41TC-150LB |

|

Norminal PRE £¨Mpa£© |

150LB |

|

Shell Pre £¨Mpa£© |

2.4 |

|

Sealing Pre£¨Mpa£© |

1.76 |

|

Operated |

Lever |

|

Leakage |

0 |

|

Suitable Tem |

¡Ü200¡æ |

|

Suitable Medium |

Sulfuric acid, such as corrosive medium |

|

Connection |

Flange |

Material of main parts

|

Name |

Body |

Seat |

Ball |

Mid body Sleeve |

Packing |

|

Matrial |

WCB |

Ind Ceramic |

Ind Ceramic |

Ind Ceramic |

High Tem Graphite |

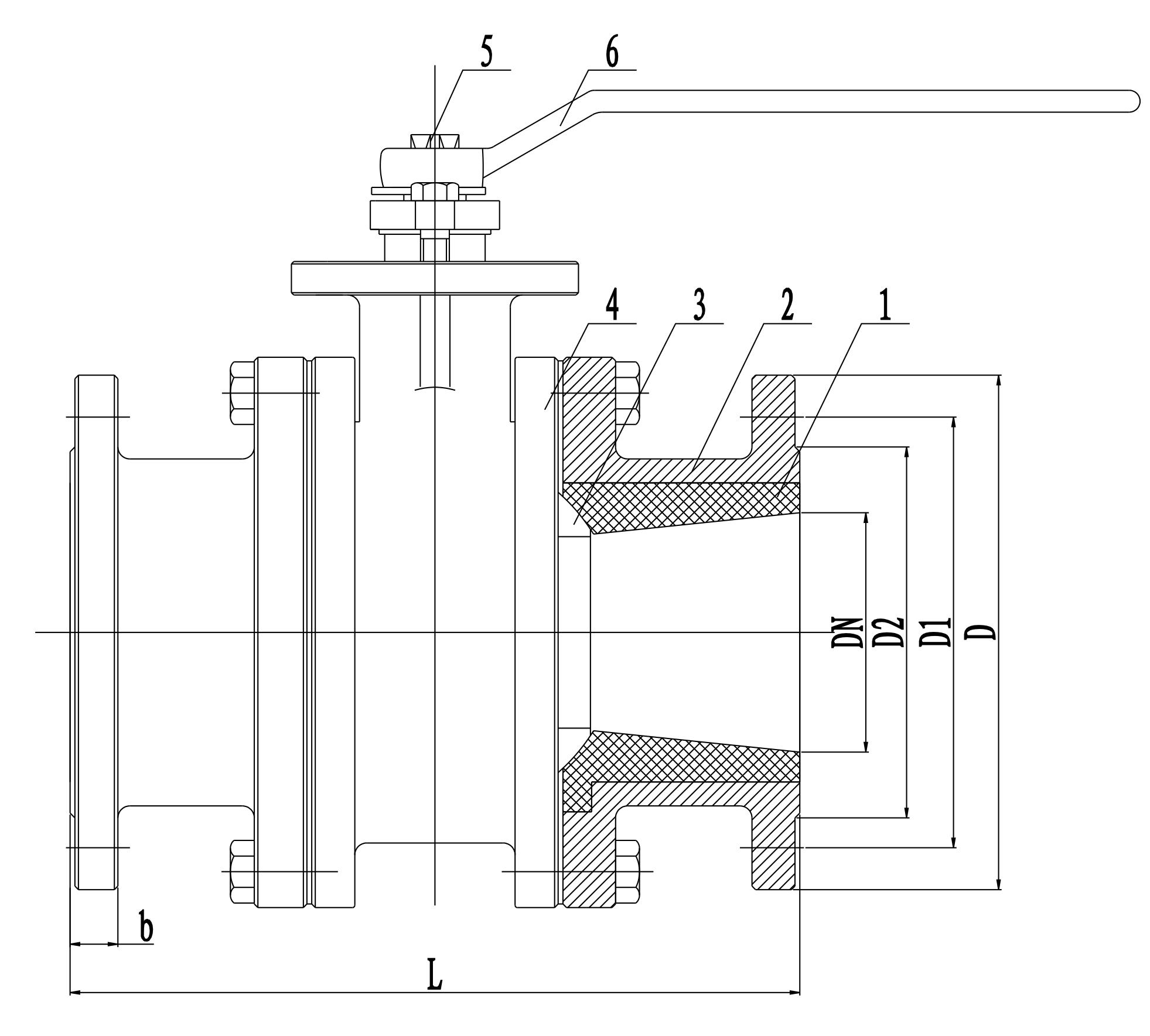

Structure drawing

1 Mid body sleeve ( runner ) 2 , Body 3 Ball 4 , Body 5 Stem , 6 Lever

Installation Notice

This valve is for the suible medium and temperature and there is no limilted of intallation angle

It must not knock when intalation

It must clean the dust in the innner champer and piping in order to be good sealing

Drivers are not allowed to do lifting .